¿Quieres que te ayudemos a diferenciarte de tu competencia?

¡Contacta con nosotros! Envíanos un mensaje o llámanos y te ayudaremos a seguir creciendo e innovando

¡Contacta con nosotros! Envíanos un mensaje o llámanos y te ayudaremos a seguir creciendo e innovando

La estampación es un proceso de impresión con diferentes técnicas tanto en frio como en caliente aplicando una película metálica sobre la superficie o material que se desea.

Algunas de las ventajas de este proceso consiste en mejorar la imagen y presentación del producto, aumenta la calidad y ayuda a destacar tu marca, es altamente permisivo en la personalización de los diseños.

Este proceso de estampación se realiza utilizando un polímero que aporta el detalle deseado en la estampación. Éste se impregnará con un adhesivo extendiendo a igual modo por la superficie a tratar y posteriormente entrará en contacto con la película del color elegido (oro, plata, metalizados, holográficos, etc.), quedando ésta transferida y como resultado el diseño esperado.

Hay tres tipos de procesos de estampación en frío FLEXOGRÁFICO | OFFSET (Convencional | Uv) |INKJET COLD FOIL.

Es el proceso de estampación más tradicional y por tanto, más extendido. Consiste en la realización de un impacto regulado en temperatura y presión sobre un poliester o película de estampación, con un cliché (molde de magnesio, latón o bronce) que previamente ha sido fijado en las máquinas de estampación.

Disponemos de una amplia gama de películas metalizadas, mates y holográficas, para trabajar con máquinas verticales, cilíndricas, rotativas y semirotativas sobre:

Consigue el relieve 3D más exclusivo del mercado. Esta técnica formulada por nuestro equipo de I+D+i utilizando nuestro barníz VM54+A serigráfico, permite alcanzar un relieve inimaginable sin aplicar ningún tipo de golpe, fácil ajuste y aplicación.

Realza tu producto con un brillo y acabado metálico y destaca sobre tu competencia.

Nuestra tecnología para estampación en plástico, ofrece un brillo llamativo efecto metálico con el que conseguirás una imagen exclusiva que te ayude a distinguir tus productos de los del resto de competidores.

Adecuado para cosmética, packaging de lujo, alimentación, perfumería, automoción…

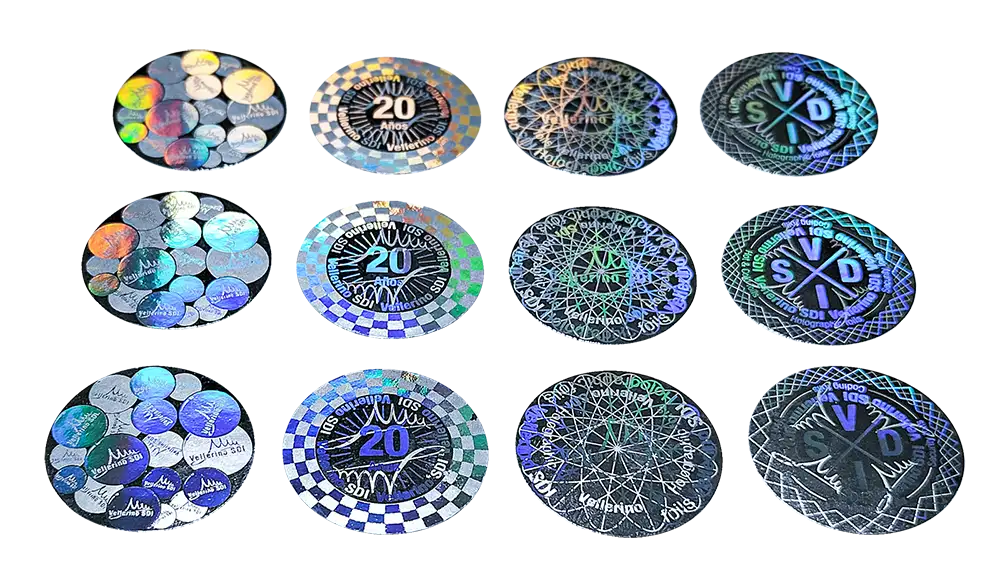

Vellerino SDI pone a su disposición una técnica innovadora a través de la cual, de una forma sencilla, usted podrá generar sus propias etiquetas con Sensación de Holograma.

Este tipo de etiqueta no pretende dar ningún tipo de seguridad al producto, sino contribuir a distinguir su etiqueta, aportando un diseño más elegante y moderno,

una fácil personalización

y haciendo más atractivo el acabado del producto final.

Soluciones seguras para la protección de marcas:

Es el proceso de estampación en caliente para decorar y estampar piezas de automóvil, revestimientos, pantallas, productos IT y electrodomésticos de alta calidad como lavadoras, ordenadores, teléfonos…

Nuestro catálogo dispone de una amplia gama de colores y acabados metálicos en brillo, mate y ultra mate y diferentes diseños holográficos, hologramas y pigmentos. Cada uno de ellos pensado para adaptarse a las necesidades específicas de tu producto y conseguir resultados de máxima calidad.

CREATIVIDAD para la impresión LASER y DIGITAL

TDFOIL es la marca de productos que Vellerino SDI presenta para hacer posible la impresión Laser o Digital con colores metalizados.

Disponemos de más de 30 colores metalizados para imprimir tus diseños y consigas realizar tus trabajos con :

Adding {{itemName}} to cart

Added {{itemName}} to cart